Data Analytics in EAM –Transforming Decision Making in Food & Beverage Manufacturing

24 April 2024

Today, the role of a Plant Manager in a food and beverage manufacturing facility is more critical than ever.

With constantly evolving consumer demands, stringent regulatory requirements, and the need for operational efficiency, staying ahead in the industry requires a strategic approach. One such strategy that is gaining momentum is leveraging big data analytics for production optimization. Let’s take a deep dive!

Understanding Big Data Analytics in Production Optimization

Big data analytics involves the systematic collection, processing, and analysis of vast amounts of data to uncover actionable insights and patterns.

In of food and beverage manufacturing, this data is typically sourced from various systems including Enterprise Resource Planning (ERP), Supply Chain Management (SCM), Manufacturing Execution Systems (MES), and other operational technologies.

By harnessing big data analytics, Plant Managers can achieve a comprehensive view of their production processes, from raw material procurement to product distribution. This visibility is crucial for informed decision-making, proactive problem-solving, and fostering continuous improvement initiatives.

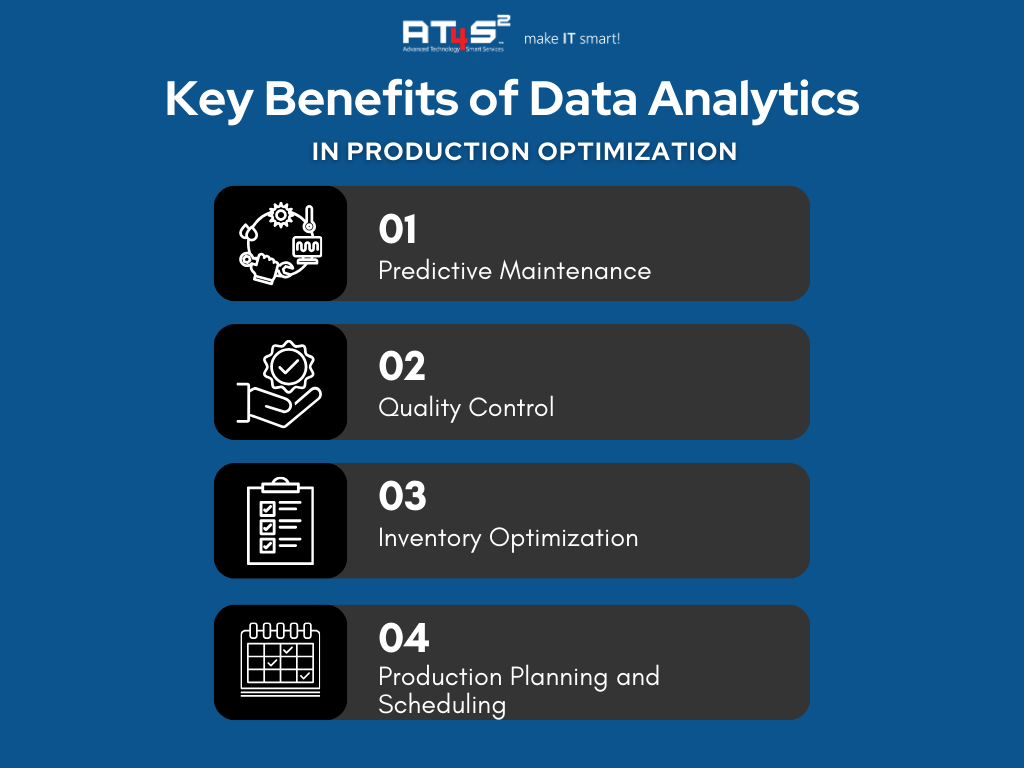

Key Benefits of Data Analytics in Production Optimization

Data analytics in EAM offers a multitude of benefits that can revolutionize food and beverage production operations. Below, we detail how leveraging these advanced analytical tools enhances various aspects of manufacturing, from maintenance and quality control to inventory management and production scheduling.

- Predictive Maintenance: Utilizing data analytics, Plant Managers can enable predictive maintenance strategies by analyzing equipment performance data in real-time. This approach helps identify patterns that may indicate potential failures, allowing maintenance to be scheduled proactively before disruptive breakdowns occur, thus minimizing downtime and maximizing asset utilization.

- Quality Control: Data analytics provides a robust framework for monitoring and analyzing quality metrics throughout the production process. Identifying trends and outliers enables managers to implement corrective actions swiftly, ensuring product consistency and adherence to regulatory standards.

- Inventory Optimization: Integrating data from ERP and SCM systems allows Plant Managers to refine inventory levels based on demand forecasts, production schedules, and supplier lead times. This not only ensures optimal stock levels but also reduces carrying costs and diminishes the risk of stockouts.

- Production Planning and Scheduling: Advanced data analytics can significantly enhance production planning and scheduling by analyzing historical production data, demand forecasts, and resource availability. Integration with advanced planning and scheduling (APS) software like PlanetTogether enables the creation of optimized production schedules that balance efficiency with customer demand.

Integration between HxGN EAM and ERP, SCM, and MES Systems

As you might know, HxGN EAM is a comprehensive enterprise asset management solution that can integrate seamlessly with a variety of ERP, SCM, and MES systems. This integration capability is crucial for leveraging big data analytics in industries like food and beverage production, where operational efficiency and timely data are key.

- SAP Integration: HxGN EAM integrates with SAP, facilitating improved asset management and maintenance operations. This integration helps align production planning with execution, ensuring that operational activities are synced with broader business objectives. This synergy offers real-time insights into asset performance, enhancing decision-making and operational agility.

- Oracle Integration: The integration with Oracle systems supports streamlined supply chain management and manufacturing execution systems. This ensures that data across financial, operational, and logistical domains is synchronized, enhancing visibility and operational intelligence. This can lead to more efficient resource allocation and better compliance with industry standards.

- Microsoft Dynamics Integration: For organizations using Microsoft Dynamics, integrating with HxGN EAM allows the utilization of Microsoft’s robust analytics and AI tools. This integration enhances the operational visibility and predictive maintenance capabilities, potentially leading to significant improvements in production processes and maintenance strategies.

- Integration with Geonexus: HxGN EAM’s integration capabilities extend to platforms like Geonexus, where it can connect with systems such as Esri ArcGIS. This connection is facilitated through the Geonexus Integration Platform, which supports no-code integration, ensuring data integrity and simplifying system synchronization across enterprise platforms.

- Advanced Data Integration with Databridge Pro: The newly introduced HxGN EAM Databridge Pro module uses Apache NiFi technology to enhance data integration capabilities significantly. This module supports complex data transformations and real-time processing, allowing for seamless data flow between HxGN EAM and other enterprise systems, IoT devices, and external applications. This level of integration is crucial for real-time asset management and predictive maintenance, which are vital in dynamic production environments like food and beverage manufacturing.

For organizations in the food and beverage industry looking to enhance their asset management capabilities, integrating HxGN EAM with these systems can drive significant value, optimizing everything from inventory management to compliance and operational efficiency. This integration not only supports operational excellence but also aligns with strategic business objectives, providing a competitive edge in a fast-evolving market.

Implementing HxGN EAM Integration with AT4 Smart Services

In summary, embracing a data-driven approach is not just a strategic imperative but a necessity for survival and growth in today’s dynamic business environment.

For organizations seeking professional expertise in implementing HxGN EAM or integrating it with existing systems, we offer comprehensive services tailored to your unique needs. Partner with us and harness the power of data analytics to elevate your food and beverage production operations to new heights.